Model 2025 Automated HTHP Cement Consistometer, 25 KSI, 400°F

Brand:

OFI Testing Equipment, Inc.

Product Code:

120-35

Availability:

Call for availability

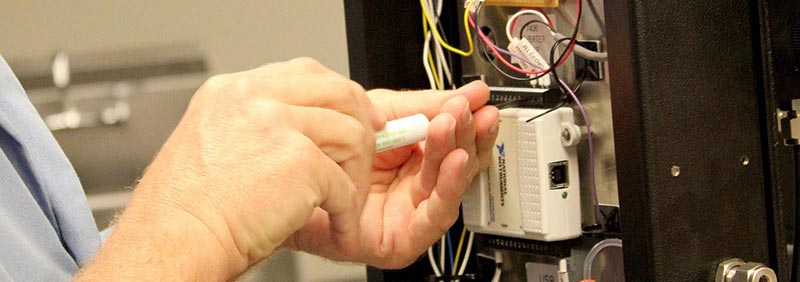

The Model 2025 Automated HTHP (or HPHT) Cement Consistometer was specifically engineered to determine the thickening time of well cements under simulated down-hole pressures and temperatures. The HTHP Consistometer offers a computerized Data Acquisition and Control system, automatic temperature and pressure control, and a variable speed motor all standard in one easy-to-use unit.

Features

- Touch-screen display

- Computerized Data Acquisition and Control system provides detailed test information in convenient formats and can control multiple units from one computer. RS-232 and Ethernet connections available.

- Automatic temperature and pressure control

- Automatic, programmable variable speed motor (0 - 150 RPM) powered by a magnetic drive

- Visual indicator provides an at-a-glance status update during testing

- Smaller cell and more efficient cooling system provide quicker cool-down times

- Small footprint saves valuable lab space

- Conforms to API Specification 10A (ISO 10426-1) guidelines

Specifications

- Maximum Pressure: 25,000 PSI (172.4 MPa)

- Maximum Temperature: 400°F (204°C)

- Consistency Range: (0 - 125 Bc)

- Digital Temperature Controller with 0.1° resolution

- Pressure indicator resolution is 1 PSI and includes both high- and low-pressure alarms

- Slurry cup rotational speed is variable up to 150 RPM

- Size: 22.5” × 27.5” × 70” (57cm × 70cm × 178cm)

- Weight: Approx. 450 lb (204kg)

- Crated Size: Approx. 26” × 34” × 76” (66cm × 86cm × 193cm)

- Crated Weight: Approx. 750 lb (340kg)

Requirements

- Air / Nitrogen supply (100 - 120 PSI)

- Water supply for cooling (40 PSI)

- Water Drain

- 230-Volt, 50 / 60 Hz, 25-Amp electrical power supply

Software Features

- Reports real-time data that can be exported to an Excel, Word, or similar file

- Enables you to program the temperature, pressure ramps, and motor speed

- Operates multiple units with one computer

Components

- #120-001: Mineral Oil, 1 Gallon

- #120-10-1: Tool Kit

- #120-102: Rupture Disk, 28000 PSI

- #120-40-032: Filter, High Pressure

- #120-40-033: Filter Element

- #120-106-002: O-ring for Filter Element

- #120-149: O-ring for Cell Cap

- #120-35-033: Air Filter

- #120-35-132: Oil Filter

- #120-40-029: O-ring for Cooling Jacket, FFKM

- #120-50-040: Wrench, Box End, 5/8"

- #120-59-076: Hose Kit

- #122-077: Fuse, 10 Amp, 5 mm × 20 mm

Slurry Cup Components

- #120-519: Slurry Cup Assembly without Expansion Chamber

- #120-521: Slurry Cup Assembly with Expansion Chamber

- #120-501: Sleeve

- #120-502: Diaphragm, Molded

- #120-502-1: Diaphragm, Flat

- #120-503: Paddle Pin

- #120-504: Pivot Bearing

- #120-505: Pivot Bearing Gasket

- #120-506: Paddle

- #120-507: Paddle Shaft, 7.75" (For Slurry Cup without Expansion Chamber)

- #120-508: Diaphragm Retaining Ring

- #120-509: Drive Disk

- #120-510: Drive Bar

- #120-511: Shear Pin

- #120-512: Drive Pin

- #120-513: Gasket

- #120-514: Drive Disk Set Screw

- #120-515: Diaphragm Support

- #120-516: Slurry Cup Base

- #120-517: Slurry Cup Locking Ring

- #120-520: Paddle Shaft, 9.125" (For Slurry Cup without Expansion Chamber)

- #122-522: Expansion Chamber Lid

Potentiometer Components

- #120-628: Potentiometer Assembly

- #120-602: Calibration Spring

- #120-603: Body

- #120-604: Resistor

- #120-605: Contact Spring

- #120-606: Contact Arm

- #120-607: Contact Strip

- #120-608: Grounding Cable Retaining Screw

- #120-609: Grounding Contact Spring

Calibration Components

- #120-35-040: Calibration Stand Assembly

- #120-75-9: Weight Hanger

- #120-75-10: Weight Set

Optional

- #120-35-SP: Spare Parts Kit

- #120-506M: Paddle for Dynamic Settling Test

Part Numbers

- #120-35: Model 2025 Automated HTHP Consistometer

- #120-35-DAS: Model 2025 Automated HTHP Consistometer with Computer

| Specifications | |

|---|---|

| Maximum Pressure | 25,000 PSI |

| Maximum Temperature | 400°F |